Craft brewing

Add our expertise and professional brewing equipment to your energy for craft brewing. Alfa Laval can help you on your unique craft brewing journey and overcome challenges. It may be the need for quality consistency, growing production target , or whether you could, actually, be doing something better? Finally, getting new equipment installed right the first time around. We have the right craft brewing equipment as well as the experience, knowledge, and shared passion to help you.

Amazing, stand-out beers

- Solutions for all brewers, by those who know their trade

- Proven track record of improved yield and reduced water and energy consumption

- Flexibility to enable you to quickly tap into new trends in craft brewing

- Local service and support across Australia

- Process and product expertise from around the world

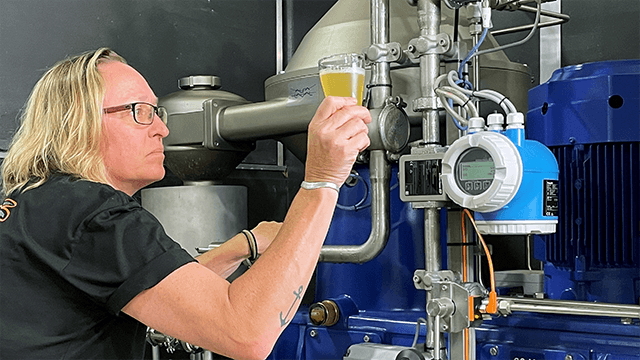

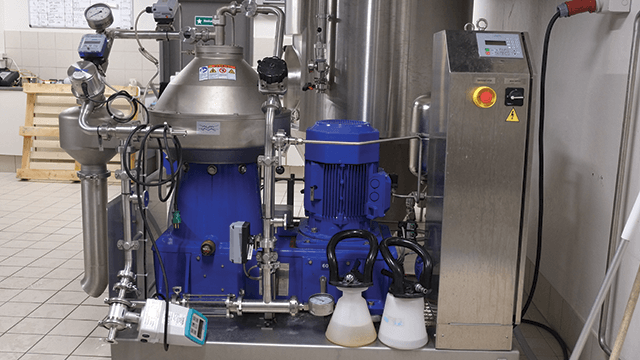

Beer centrifuges

Alfa Laval beer centrifuges have a long history of enabling breweries around the world to achieve higher yields, meet shifts in demand and maintain profitability. Used in pre-clarification, green beer separation, hot wort separation and beer recovery, they ensure minimal levels of oxygen pick up during passage through the separator and the highest standards of hygiene.

Carbonation modules

The Alfa Laval Carboset™ and Carboset™ Mini are beer carbonation systems, both excellent for accurate, automatic and low-maintenance beer carbonation and carbonation of other beverages, including soft drinks. Our beer carbonation machine is designed to fit the desired level of carbon dioxide in beer as well as the need for nitrogen in beer to match your perfect recipes.

Cleaning in Place

The Alfa Laval CIP station is a modularised skid-mounted plug-in unit for automated cleaning-in-place of brewery process installations, including process piping, tanks, filling machines and heat exchangers, among other systems. The cleaning regime is fully adjustable to that required by the target system in terms of cleaning time, temperature, pressure and flow.

Deaerated (DA) water

Produce high-quality deaerated water efficiently and hygienically with the Alfa Laval Aldox™ Mini. This factory-assembled system, developed in cooperation with the brewing industry, is designed as a skid-mounted unit that is easy for craft brewers to instal and operate. Cleaning-in-place is integrated into the deaerated water unit so you benefit from easy, automatic maintenance.

Dry hopping

Alfa Laval has solutions for all main stages of the dry hopping process: pellet introduction, disaggregation, aroma and flavour extraction as well as removal of hop material. The Alfa Laval solutions for dry hopping are designed to help brewers produce distinctive beers while maximizing yield, minimizing process time, improving cleaning procedures and minimizing losses.

De-alcoholisation module

Alfa Laval’s fully automated Beer dealcoholizers are plug-in solutions that remove alcohol efficiently and gently in a single-pass to produce full-flavoured beers. They are designed to help brewers tap into fast-growing and profitable low and no-alcohol beer market as people search for healthier options. The modular design makes it simple to add non-alcoholic brewing capability without the need for major capital investment.

Eliminate the challenges in the brewing process with our brewing equipment

Improving operations is an everyday fact of life for brewers, all the way from the brewhouse to packaging. Incremental improvements to wort yields, beer loss or water usage can amount to significant savings over the long term. See how our brewing process expertise, solutions and individual components for each process block help avoid and overcome common issues in the brewing process.

Brewhouse

Recover wort, reduce waste, save energy and improve brewhouse efficiency and hygiene.

Coldblock

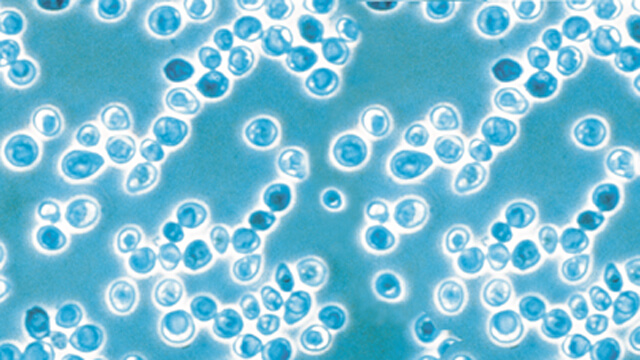

Recover beer, shorten beer fermentation and maturation time, improve yeast management, sampling and more in the coldblock.

Filtering and treatment

Avoid spoilage, improve beer quality and diversify your products.

Preparation of lines & Cleaning

Optimize cleaning and preparation of lines and tanks.

Craft brewing process

Equipment for optimal craft beer brewing

The craft of making beer blends complex processes with creative artistry. Bridging the gap between brewing theory and practical craft brewing comes from the experience to spot signs of trouble and the knowhow to respond to them. This is where combining expertise can yield benefits stretching from the brewhouse to packaging. Issues can be controllable and avoidable, given the right brewing equipment and the right application.

Alfa Laval does not only make brewery centrifuges, but offers brewers a market leading range of hygienic fluid handling products (i.e. tank cleaning, pumps and valves) as well as process solutions for beer production including deaerated water (DA water), dry hopping, wort modules, de-alcoholisation, CIP stations and yeast propagation. Alfa Laval hygienic heat exchangers allow you to recover and re-use heat from processes to reduce your carbon footprint and save money on energy.

See our full range of process knowledge and craft brewing solutions.

Service you can rely on

For brewers, having local support for your equipment is an absolute priority. With Alfa Laval, you have peace of mind with after-sales service and technical support around Australia with your purchase. With a regional presence across NSW, VIC, WA and QLD, Alfa Laval’s highly skilled field service technicians provide commissioning, maintenance and repairs onsite in both metropolitan and remote areas. The Alfa Laval service centre located in Sydney is equipped for full centrifuge support ranging from maintenance and cleaning to coating, welding and bowl balancing.