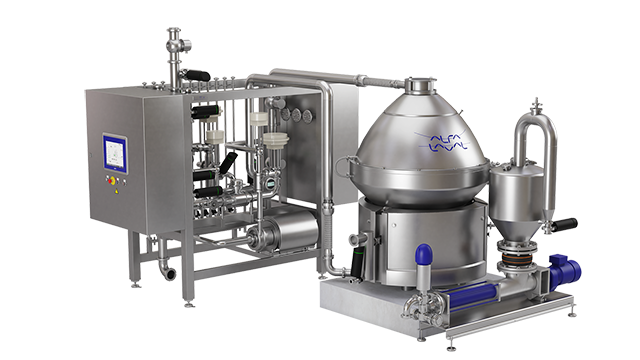

Brew series

Alfa Laval beer centrifuges have a long history of enabling breweries around the world to achieve higher yields, meet shifts in demand and maintain profitability. Used in pre-clarification, green beer separation, hot wort separation and beer recovery, they ensure minimal levels of oxygen pick up during passage through the separator and the highest standards of hygiene.

High beer separation efficiency combined with energy efficient operation

- Centrifugation provides breweries with swift beer clarification with no loss of aroma

- Increased clarification capacity: reduced fouling of filters with preclarification

- High efficiency beer separation enables quicker turnover of fermentation tanks

- Reduced product losses: beer centrifugation results in more concentrated solids compared to gravity settling

- Patented beer brewing equipment and hermetic design leads to low to zero oxygen pick up

Need more details? We are here to help!

Request pricing for Alfa Laval Brew Centrifuge range and talk to one of our brewery specialists to find out which centrifuge size and type is best suited to your requirements.

Brew range

Brew 20

Multi-purpose centrifuge for craft brewers and microbreweries

- Up to 15 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Simple to operate

- Plug & Play skid

- Low maintenance costs

Want to know more about our smallest beer brewing centrifuge? Read more about Brew 20

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Basic and easy to operate

- Plug & Play skid

Brew 80 Plus

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Basic and easy to operate

- Plug & Play skid

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

Brew 301

Multi-purpose centrifuge for small breweries

- Up to 200 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 250

Polisher and multi-purpose centrifuge for small breweries and сraft brewers

- Resource efficient clarification up to 180 hl/h

- ProCarb - Inline carbonation option available

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 250 Plus

Polisher for small breweries and craft brewers

- Up to 180 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 350

Polisher and multi-purpose centrifuge for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 350 Skid

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

-

Up to 60% energy savings when compared to traditional design

Brew 450

Pre-clarification and polishing duties in medium size breweries

- Up to 550 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

-

Up to 60% energy savings when compared to traditional design

Brew 501 H

Multi purpose for larger size breweries and craft brewers

- Up to 500 hl/h

- Center to Center

- Zero oxygen pick-up and low power consumption

- Complete system with full flexibility

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 600

Multi-purpose for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 600e

Multi-purpose for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Brew 701

Polisher for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 701e

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Very low power consumption with eDrive (direct drive)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Brew 701 eMotion™

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Extremely low power consumption with eDrive (direct drive) and eMotion (reduced air friction)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Brew 750

Pre-clarification and polishing duties in large breweries

- Up to 1000 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

-

Up to 60% energy savings when compared to traditional design

Brew 750e

Pre-clarification and polishing duties in large breweries

- Up to 1000 hl/h

- Hermetic Design™ offers close to zero oxygen pick-up, guaranteed to be below 5 ppb

- Up to 60% energy savings when compared to traditional design

Need more details? We are here to help!

Request pricing for Alfa Laval Brew Centrifuge range and talk to one of our brewery specialists to find out which centrifuge size and type is best suited to your requirements.

Upgrade options for inline carbonation

ProCarb

- Boost productivity with rapid clarification and carbonation

- Save space with no need for extra equipment

- Reduce oxygen pick-up with advanced centrifuge design

- Get precise process control with easy-to-operate system

Happy brewers

Everything you need to know about beer centrifuges

Why should you centrifuge beer?

How does a beer centrifuge work?

What is the difference between filtration and centrifugation?

How to choose the right centrifuge size?

Why would a small craft brewery consider a centrifuge [VIDEO]?

How can a centrifuge improve the flavour and aromas of your beer [VIDEO]?

Why would you want a centrifuge when you brew hazy beers or stouts [VIDEO]?

How can a centrifuge help you scale up production [VIDEO]?

What are the financial benefits of a centrifuge [VIDEO]?

Does installing a centrifuge increase the risk of dissolved oxygen [VIDEO]?

How a centrifuge helps craft brewers meet demand for premium beers?

Maintenance and service for top performance

A breakdown is a costly exercise, which can lead to high storage costs and even product spoilage. From leaks and improper discharge to mechanical seal failure, many issues can be prevented by a regiment of regular service intervals provided by a qualified technician, following proper Cleaning-in-Place (CIP) procedure and changing the oil regularly. Learn what to look out for and how to prevent downtime

Explore our innovations

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Craft brewing

Share your passion for craft brewing

Commercial brewing

The best equipment for the best beer