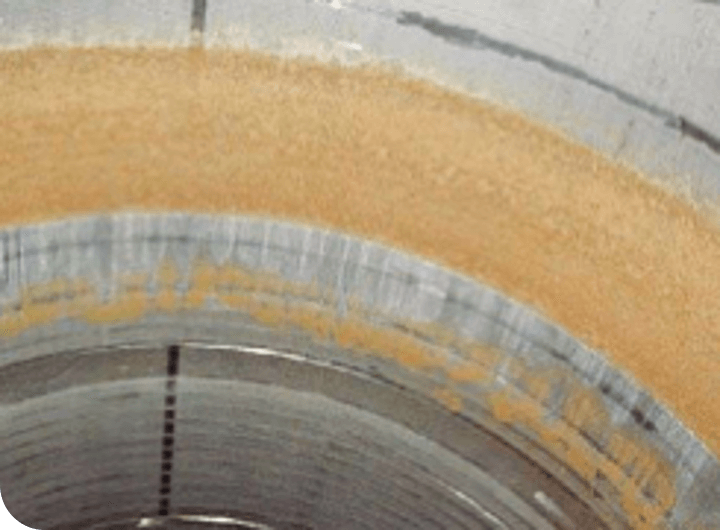

How to remove stubborn yeast rings (Krausen ring)

One of the most worrisome challenges faced by a brewer is the risk of microbiological spoilage. That is why tank cleaning is one of the most important operations to get right.

Benefits of rotary jet heads for tank cleaning

How to clean fermenters with yeast rings is a challenge for brewers. The most common solution is to use static spray balls. While they deliver quick wetting, but low action. That translates to inefficient and expensive cleaning.

Rotary spray heads, by contrast, have lower water consumption, greater cleaning efficiencies and significantly reduced operating cost than static spray balls. They clean the tank with a more efficient a 360 degree indexed pattern and ideally come with enhanced self cleaning features to prevent contamination of the spray head even when the head was immersed in foam (Krausen) during fermentation.

To compare products, consider the mechanical cleaning action (wall sheer stress) measured in Pascals (Pa) that the tank cleaning spray ball can deliver.

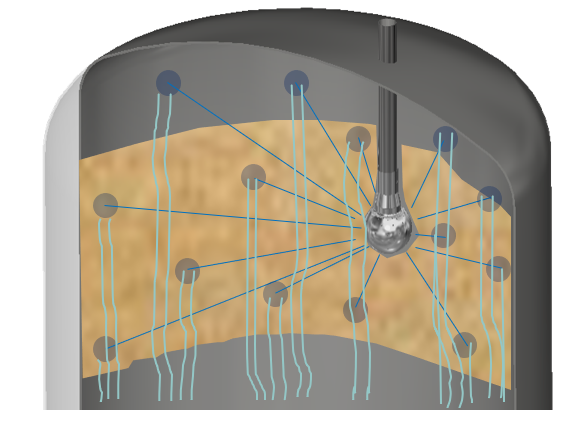

Cleaning pattern of a static spray head on yeast ring

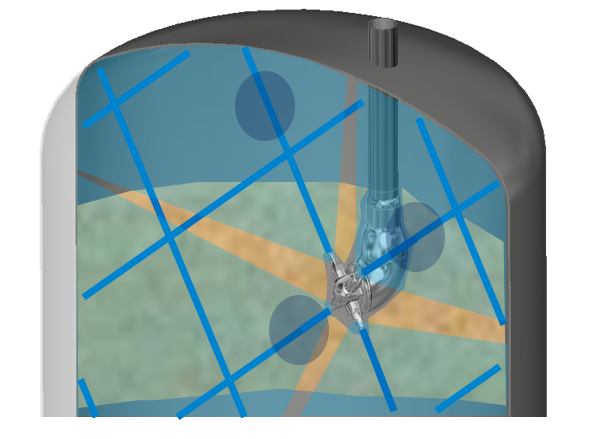

High impact cleaning of a rotary jet head by comparison

Product spotlight

TJ40G for the most challenging tank cleaning tasks

The Alfa Laval TJ40G provides automated 3D-indexed impact cleaning over a defined time period for processing, storage and transportation tanks and other vessels between 50 and 500 m3. The design is suitable for cleaning brewing equipment as a cost effective means of achieving hygienically safe and quality assured tank cleaning.

Burst cleaning is a major trend in the brewery industry

Burst cleaning means applying the caustic directly to the tank without wetting first. Some or all of the caustic go to the drain (sacrificial caustic) however it is used in small amounts. When the caustic is running clear, the tank is clean and solids have been removed. This method reduces cleaning time and with that production downtime significantly.

Product spotlight

Alfa Laval TJ40G Burst is a rotary jet head tank cleaner with a special nozzle that enables fast chemical wetting of the tank to help reduce cleaning time and water and chemical usage. With the TJ40G Burst which is specifically designed for burst cleaning you can get full coverage of the yeast ring in one cycle in 1-2 minutes.

Considerations for retrofitting

If you’re thinking of retrofitting your tanks with rotary jet heads, there is a number of factors to consider:

-

Your tank top plate – the jet head might not fit through the flank. Consider the Scandi Brew Tank Top plate to ensure the rotary jet head can be installed and the sight glass is in the ideal distance from the jet head.

- Valves – in pressurised tanks, you need to be careful that no gas can flow through the rotary jet head. To avoid this scenario, replace no return valve with two automated butterfly valves

- CIP Pumps – ensure correct pressure

- Process piping for cleanability. Avoid dead legs in piping branches which can pose a hygienic risk with double seat Mixproof valves. Seat lift Cleaning in Place is more hygienic than external valve CIP and saves 70% of water and CIP chemicals. You will need more seat lifts for beer (2-5) and cold wort (5-10) than for other beverage process such as dairy.