Water & Wastewater treatment in Australia

Water is quickly emerging as the most critical resource on the planet. Environmental, regulatory and operational considerations for water management mean choosing the right process and equipment for wastewater treatment has never been more important. With solutions and competences accumulated over many decades and industries, Alfa Laval empowers municipal and industrial plants to optimize their water footprint by focusing on water conservation, wastewater treatment, water reuse and the establishment of circular water systems.

Why is wastewater treatment necessary?

Water & wastewater treatment is a crucial process that involves removing contaminants and pollutants from domestic (also called sewage or municipal wastewater), industrial, and commercial wastewater and sludge. Choosing wastewater treatment processes and wastewater equipment manufacturers that can deliver the desirable improvements in environmental, financial and operational metrics is vital, backed by strong technical support to maximise performance and minimise total cost of ownership.

Which wastewater treatment is most effective?

There are many types of equipment required for wastewater treatment, and the specific equipment used depends on the type and scale of the wastewater treatment plant.

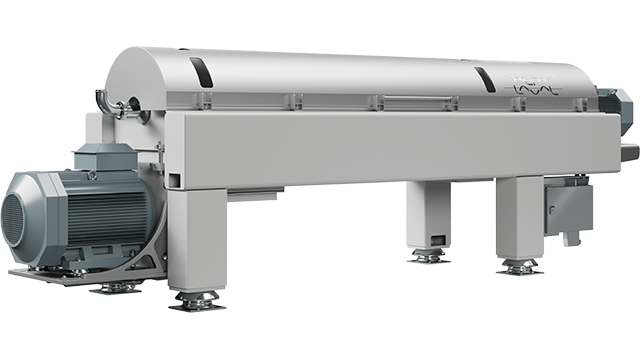

To reduce sludge volume, waste disposal cost and meet sustainability requirements, on-site sludge thickening and sludge dewatering is a fundamental part of all current wastewater treatment processes It is also highly relevant for sludge to be used as digester feed for biogas production, thermal processes and composting.

Pre-heating of wastewater sludge prior to sludge dewatering can also cut costs and provide an opportunity for heat recovery. Thermal equipment can also be used for sludge digestion to produce biogas and for sludge hydrolysis and pasteurization.

>> Learn more about sludge dewatering, thickening and thermal sludge treatment

Alfa Laval offers a comprehensive portfolio of advanced equipment for municipal and industrial wastewater treatment to reduce the environmental footprint from water and waste streams, and lower your operating costs, including tertiary filtration, and sludge thickening and dewatering.

Contact our local wastewater experts to find the most effective solution for your application

Most popular industry or application information:

Most popular products:

Is wastewater treatment sustainable?

Only 1% of the world’s water is drinkable, and managing water as a precious resource aligns with United Nations’ Sustainable Development Goals. Wastewater treatment can be made more sustainable focusing on strategies towards water stewardship and energy-neutral resource recovery plants.

What is zero liquid discharge for wastewater?

Zero liquid discharge (ZLD) is a wastewater treatment process that aims to eliminate the discharge of any liquid waste by recovering all of the water from the wastewater and converting the remaining solids into a dry, solid waste material, leaving only clean water behind.

In a ZLD system, wastewater is treated through multiple stages of treatment processes. It involves treating the concentrate through thermal or mechanical processes, such as evaporation, crystallization, or spray drying, which results in the formation of a solid waste material that can be disposed of in a landfill or used as a fertilizer.