Sharpe Engineering discovers a smarter way to clean coolants

Sharpe Engineering is an Australian, family owned company based in Queensland that provides quality driven engineering and manufacturing solutions since 1995. The company’s clients include operators, contractors and service providers across Australia’s significant resource and energy sectors. Quality is a major focus for the business in the manufacture, servicing and repairing of drilling, casing and wellhead related tools and equipment. As the business is expanding, coolant usage and disposal cost have been increasing substantially. We speak with Jon Sharpe, General Manager at Sharpe Engineering, about the industrial coolant challenge and his company’s new way to remove contaminants.

DATE 2025-03-03

Jon Sharpe, General Manager at Sharpe Engineering

How would you describe the coolant problem for your business?

Sharpe Engineering is growing– we started with our first workshop in Roma, Queensland, then added two sites in the Brisbane area. We deliver specialised products and services to Australia’s Oil and Gas sector and employ almost 100 employees.

Coolant treatment is a problem for us. Particles enter the coolant system, and these fine metal shavings affect the quality of the coolant fluids over time. We had to dispose of our coolant every year to keep it at a good consistency. Disposal is expensive at a cost of almost $1 per litre with a specialised waste disposal company.

Due to our business expansion, our equipment is getting bigger. With that, our coolant tanks were getting bigger, and cost were increasing. Currently, our biggest machine is attached to a 1,700 litres coolant tank, the other units average 600 – 700 litres per tank. In Brisbane we have 12 machines alone.

Were rising disposal cost the only problem?

The indirect cost are even more significant. We spend a lot on cutting tools, easily hundreds of thousands of dollars. That’s why it’s important to protect our cutting tools. The particles in the coolant damage the tools over time and you can’t remove them with skimmers.

Staff morale and health are another important factor. The coolant deteriorates over time and I can tell you that it’s not fun for the operators to work with stinky coolant. Some people can get a rash.

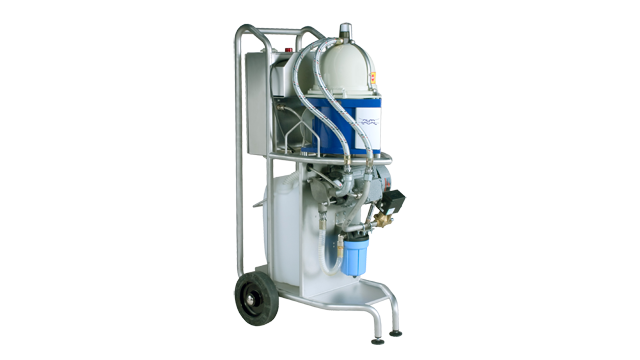

What is different with the Alfa Laval Alfie 500?

It was our coolant dealer who recommended the Alfie separator. We investigated the Alfa Laval product and found that it’s a superior and extremely cost-effective way to prolong the use of our coolants. The Alfie 500 centrifugal separator was simple to install and is easy to run and clean.

Alfa Laval sent one of their local service technicians to install and explain the different parts of the separator. It made all the difference to have Brisbane based technical support.

Now our operators have been trained to use the Alfie and it’s running non-stop. It rips all the oils and particles from the coolant. We expect a rapid Return on Investment from savings on disposal cost. This is in addition to savings on cutting tools and seeing happier employees.

What’s your recommendation for metalworking businesses in similar situations?

I recommend looking after your coolant. The right coolant treatment has a great effect on the quality of work and the staff morale. And reducing the disposal cost for waste coolant has a direct impact on your bottom line.

At a glance

- Founded in 1995

- Approx. 100 employees

- 12 machines in Brisbane workshops alone

- Had to dispose of coolant every year

- Disposal is expensive at a cost of almost A$1 per litre

The Alfie 500 is a superior and extremely cost-effective way to prolong the use of coolants. Now that Sharpe Engineering's operators have been trained to use the Alfie, it’s running non-stop. It rips all the oils and particles from the coolant.

We expect a rapid Return on Investment from savings on disposal cost. This is in addition to savings on cutting tools and seeing happier employees.

Product highlight: Alfie 500

The Alfa Laval Alfie coolant cleaners are a proven way to use your coolant at least 3-5 times longer. This dramatically reduces the volume of waste coolant to be sent to disposal and waste management facilities. A centrifugal separator removes tramp oil and other contaminants such as fine metal shavings. Protect your expensive cutting tools in CNC machines and remove odour in your workshop with the Alfie