2024-01-18 Product news

Transform wastewater for sustainable future at Ozwater’24

While demand for wastewater treatment is growing in Australia, choosing the right process and equipment for wastewater treatment has never been more important to meet environmental, regulatory and operational requirements.

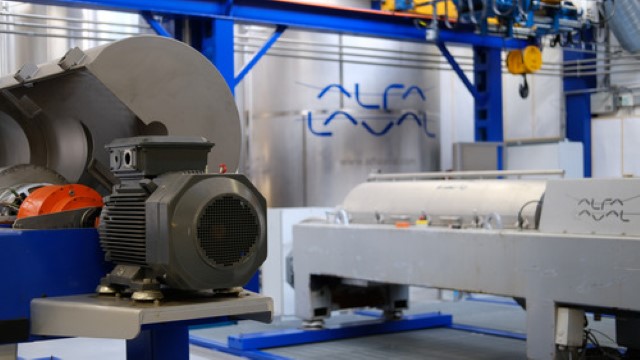

Alfa Laval is pleased to exhibit at OzWater’24 (Melbourne, 30 April – 2 May 2024) with its market leading wastewater decanter technology, and a raft of other innovative products and services focusing on water conservation, wastewater treatment, water reuse and the establishment of circular water systems.

With solutions and competences accumulated over many decades and industries, Alfa Laval helps you move towards an energy-neutral resource recovery plant. We know that by applying the most energy-efficient solutions, municipalities can optimise their energy consumption. There is also ample opportunity to recover heat from multiple process steps as an energy source or generate energy from methane, together with the recovery of resources.

This is backed by our unrivalled local service network with service centres, field service engineers, and authorized service providers across Australia.

Highlighted products & solutions

Solutions for Sludge Treatment & Thickening

To reduce sludge volume, waste disposal cost and meet sustainability requirements, on-site sludge thickening and sludge dewatering is a fundamental part of all current wastewater treatment processes. Dewatering and thickening equipment such as decanters and rotary drum filters are also highly relevant for sludge to be used as digester feed for biogas production, thermal processes and composting.

ALDEC>> Visit ALDEC |

ALDRUM>> Visit ALDRUM |

Discover more Alfa Laval innovations

Membranes

Membrane bioreactor technology is a future-proof solution for treatment of both municipal and industrial wastewater. It allows you to maximize resource recovery, minimize costs and implement a circular-economy perspective in your operations. Membrane technology allows removal of hazardous pollutants –including PFAS and microplastics - with solutions that can even meet the strict requirements of the revised EU Urban Waste Water directive. >>MBR membranes

Zero Liquid Discharge

Turn waste into value with an Alfa Laval AlfaFlash ZLD system. These robust, compact solutions increase water usage efficiency by removing liquid waste and treating water for reuse, at a lower investment, installation and operational costs compared to traditional evaporation technologies. ZLD systems are designed to meet the needs of a broad range of applications including industrial waste streams and municipal wastewater treatment. >>AlfaFlash ZLD

Spiral Heat Exchangers

Pre-heating of wastewater sludge prior to sludge dewatering can cut costs and provide an opportunity for heat recovery. Thermal equipment can also be used for sludge digestion to produce biogas and for sludge hydrolysis and pasteurization. >>Welded spiral heat exchangers

Meet Alfa Laval Experts

Mikael Eklund, Global Technology, Regional Business Manager – Water & Waste Elements

Mikael Eklund is a Global Technology, Regional Business Manager in Alfa Laval who focuses on water and waste elements in South East Asia, South America, Benelux & Nordic.

Mikael Eklund is a Global Technology, Regional Business Manager in Alfa Laval who focuses on water and waste elements in South East Asia, South America, Benelux & Nordic.

He holds a degree from IHM Business School and has been with Alfa Laval for 12 years with massive experience and knowledge in decanter business and technology under his belt.

Bala Kanesha, Sales Engineer – Waste Water

Bala’s experience spans more than 18 years’ experience working in the water and wastewater industry from a chemical (coagulants & flocculants) and process optimisation perspective, across both Australia & New Zealand.

Bala’s experience spans more than 18 years’ experience working in the water and wastewater industry from a chemical (coagulants & flocculants) and process optimisation perspective, across both Australia & New Zealand.

He recently joined Alfa Laval’s Food & Water Division with responsibility for decanters and rotary drum thickener equipment. Bala brings a good mix of commitment and technical expertise within the water & wastewater industry to the role to help customers optimise their processes for profitability and sustainability.

Douglas Wood, Sales Manager – Protein & Waste Water

Doug’s experience encompasses more than 24 years working within process industries specialising in protein and wastewater. He started his career hands on, doing repair and maintenance of industrial dewatering equipment for more than a decade as service engineer.

Doug’s experience encompasses more than 24 years working within process industries specialising in protein and wastewater. He started his career hands on, doing repair and maintenance of industrial dewatering equipment for more than a decade as service engineer.

He moved to sales in 2010 for both service and supplying new equipment for Alfa Laval, and has recently taken on a regional role for decanter technologies helping customers in the protein and wastewater industries optimise process and business outcomes.

Towards an energy-neutral resource recovery plant

At a glance

Visit Alfa Laval at stand N13

About Ozwater’24

Ozwater is the biggest water conference and exhibition in the Southern Hemisphere, running for three days annually.

Ozwater’24 will be held at Melbourne Convention and Exhibition Centre from Tuesday 30 April to Thursday 2 May 2024. Its theme, Accelerating Action, is a rally cry to our community addressing the vital role water must play in the climate crisis of our current time. Together, we will ignite a powerful movement towards a sustainable water future. Ozwater’24 will take concrete steps to effect lasting change. More details about Ozwater’24 can be found at www.ozwater.org