Municipal wastewater treatment

Alfa Laval helps reduce the environmental footprint from water and waste streams, by maximizing reuse of water, by turning waste to value, and by minimizing energy consumption and waste. We offer a complete spectrum of wastewater treatment equipment, filtration and sludge treatment that helps produce clean effluent water for discharge or water reuse, recover heat and reduce the amount of sludge for disposal.

Why Alfa Laval for water and wastewater treatment

- Recover valuable resources from main process

- Minimise waste for disposal

- Cost-efficient production

- Reduce environmental footprint

- High performance and low TCO with unrivalled service support across Australia

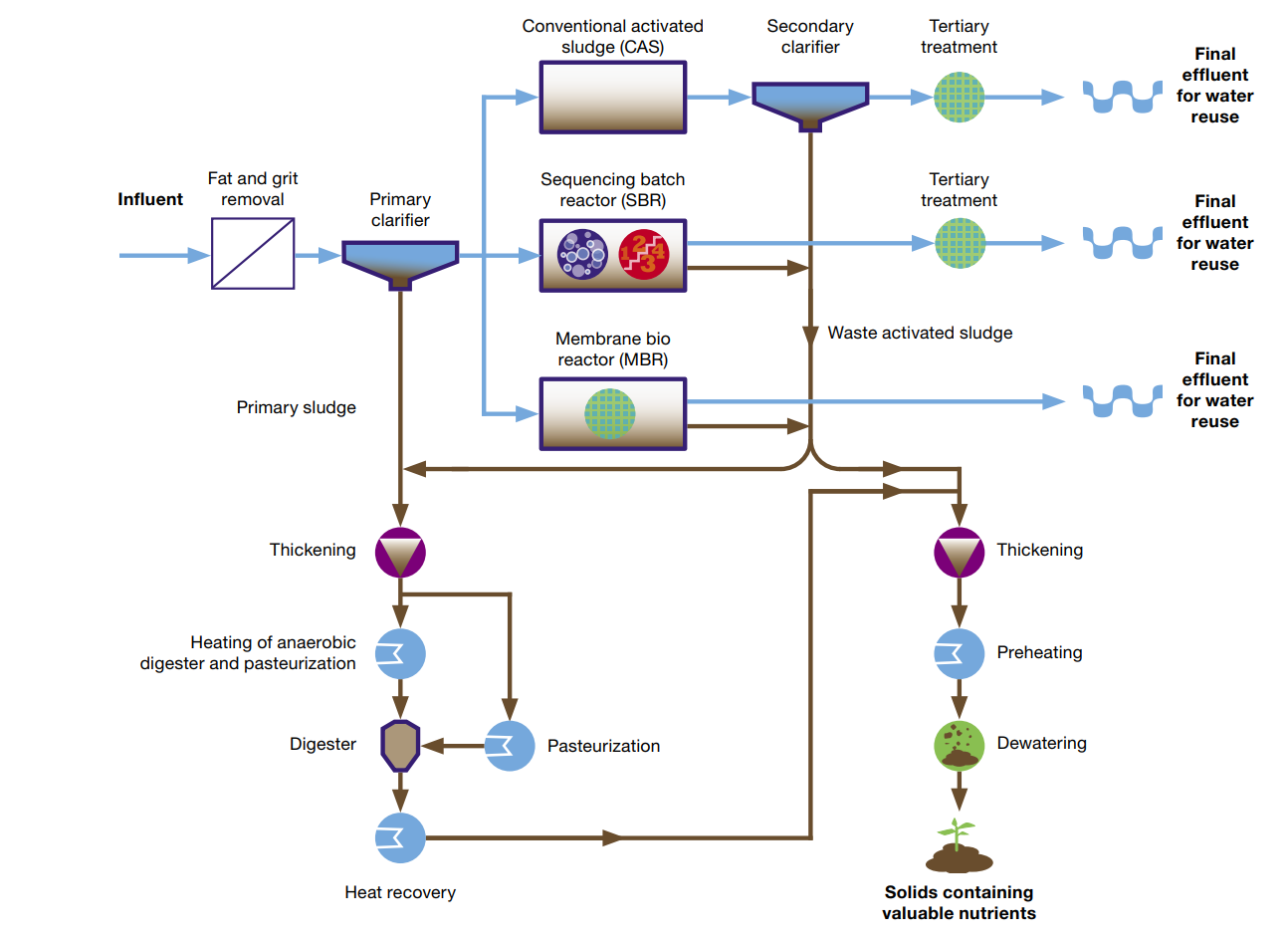

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

Process and product overview

With Alfa Laval as your partner, you gain the dual advantage of access to leading wastewater expertise as well as one of the widest ranges of wastewater treatment equipment.

Wastewater filtration

Sludge dewatering

Sludge thickening

Sequencing batch reactor

Biological wastewater treatment

Heat Exchangers

Products and knowledge to help you optimize your industrial or municipal wastewater treatment plant

Our wastewater treatment experts are happy to assist contractors, designers and plant operators by giving advice on how to optimize operations. Regardless of whether it is an industrial or municipal wastewater treatment plant, new or old, we can help you:

- lower the total operating costs (energy, maintenance, etc.)

- maximize resource reuse (water, nutrients)

- reduce energy use, polymer consumption and disposal costs

- optimize cake dryness and effluent quality

- increase capacity

- minimize engineering and investment costs

- reduce installation and start-up costs

- ensure on-time project completion

- optimize investment and operational costs

Bid to win with world-leading decanter technology

Alfa Laval is proud to work with Engineering, Construction and Service partners and consultants on delivering successful upgrade and greenfield projects as decanter equipment partner of choice. Find out how we can support you and your project from bidding and commissioning to after sales support and OEM parts.