The challenges and solutions around mining tailings

The blog of Amol Chinchankar, Mining & Minerals Industry Manager, and Alfa Laval mining tailings experts from around the world.

Amol is a Chemical Engineer with a Masters in Business Management. He has more than 25 years of work experience and specialises in business development and application engineering of Solid-Liquid Separation technologies. As Manager for the Mining and Minerals Industry at Alfa Laval, Amol helps miners optimise their processes, generate operational savings and open up new revenue channels,including in areas such as safe and sustainable tailings management.

Mining industry and tailings best practice

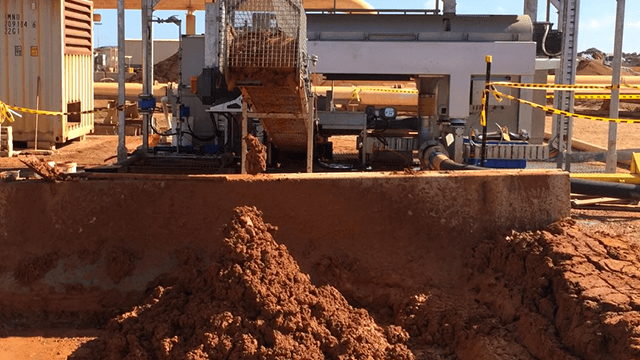

One of the biggest challenges facing the mining industry is how to dewater mining tailings. Now that awareness is more widespread, best practices are emerging.

Dry tailings solutions

Dewatering mine tailings is an essential practice, and multiple solutions exist which all make the same promise. Which is best for your business?

Dewater slurries with slimes and ultra-fines

Slimes and ultra-fines present a challenge to metallurgists and tailings engineers. What are the tailings disposal options for affected sites?

Gain confidence with a trial

Slurry mineralogy can vary significantly between different mine sites. Learn how a trial helps determine the dryness of the cake.