Australia’s top technologies for long duration energy storage

With an abundance of land, sun and wind, Australia has long been hailed as an ideal location for renewable energy generation. According to the Clean Energy Council, more than 50 large-scale solar farms under construction, and the country could even become a major exporter of clean energy to neighbouring Asia and beyond.

DATE 2023-11-27One of the critical questions to ensure a smooth energy transition to reliable, low cost clean energy is how overcome intermittency while stabilising the grid.

A vibrant start-up community, with backing by some of the largest energy companies as well as state and federal government agencies, is bringing long duration energy storage from R&D to commercial scale to make this vision a reality. Contrary to common belief, many of the technologies are available today, leveraging tested and proven heat transfer technologies.

We speak to Neil Wissemann, Alfa Laval’s Technical Sales Engineer, who is based in Brisbane, to find out more about the technology choices for long duration energy storage, and how they compare.

Can you explain more about renewable energy and long duration energy storage in the Australian context?

Here in Australia, we are mostly talking about renewable energy and solar. Organic Rankine Cycle (ORC) has been recognised as a promising thermal energy technology to convert low-grade heat energy into power. You can use heat energy from solar to create a hot storage, or use spare electrical energy to create cold storage. ORC adoption is still limited, due to the cost of the equipment compared to the amount of power. But you can improve its efficiency to get more power output from a particular system, or reduce your capital expenditures of the equipment that you're installing.

Alfa Laval’s heat exchangers, used as either evaporator or condenser in the ORC system, are able to help improve efficiency of the system and reduce capital expenditures. By having a heat exchanger between your heat source and the ORC system, you can get closer temperatures, which will help maximize the power output from the system.

What is your advice to companies designing ORC systems? What support is Alfa Laval offering?

Technology is ever-changing; hence, it’s important to keep on innovating. There is now basically different applications emerging for the ORC system due to renewed interest driven by the goals to break down carbon emissions, to reach carbon targets, and to address various environmental concerns.

Alfa Laval is the leader in heat transfer for heat recovery technologies. With our global presence and experience in thermal performance optimization, as well as superior technology, it is no doubt that Alfa Laval is the perfect partner.

How has Alfa Laval’s plate heat exchangers help achieve optimal efficiency for innovative solar energy storage? Can you share any success story?

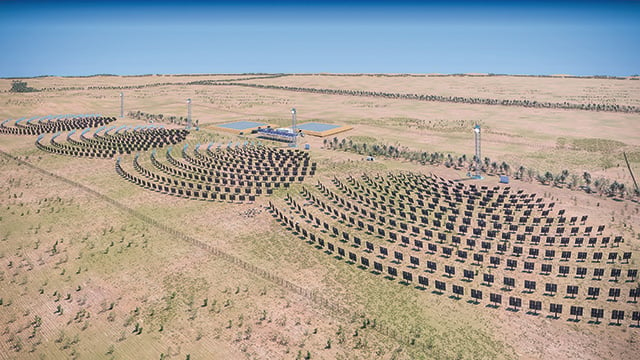

With our global presence and expertise in thermal performance optimization, Alfa Laval has partnered with many companies. When cleantech start-up company, Raygen, built the world’s first PV Ultra and Electro Thermal Storage power plant in Victoria, Australia, which captures sunlight using mirrors and stores energy in water, Alfa Laval provided plate heat exchangers to optimize energy efficiency and system design.

Alfa Laval provided deep knowledge in system design development as well as support and important insights to the projects development. With energy stored as hot and cold water, RayGen’s patented technology allows to generate electricity during the night at half the cost of lithium-ion batteries using the ORC turbine.

Which alternatives are available for long duration energy storage?

Today our heat exchanger technologies can already be found playing a critical role in innovative new energy storage projects, such as thermal storage, compressed air energy storage (CAES), liquid air energy storage (LAES), pumped heat energy storage (PHES), molten salt energy storage and many more. Alfa Laval continues investing in clean energy R&D and innovation to accelerate sustainable solutions.

Meet the expert

Neil Wissemann

Thermal Sales Engineer, Alfa Laval Australia

Neil Wissemann has worked for Alfa Laval for 14 years, providing thermal solutions to industrial customers. Using this background, he is now able to help Clean Tech companies and start-ups maximize their energy efficiency while remaining cost competitive. Neil has a special focus on thermal storage solutions, minimizing liquid waste, carbon capture and battery minerals.