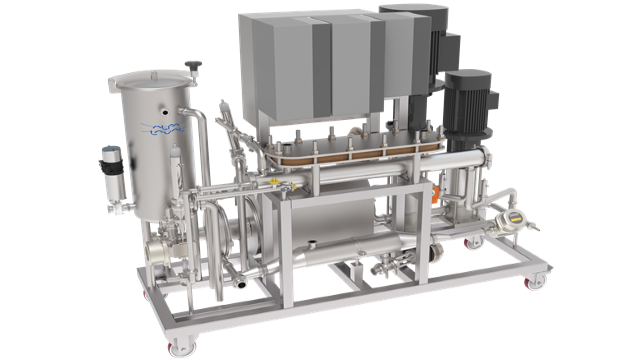

UF spiral

The Alfa Laval ultrafiltration spiral membranes (UF) are a proven and popular choice for many processes in the food, beverage, dairy, biotech and pharmaceutical industries where they are used for product recovery as well as product purification, fractionation and concentration. This makes the ultrafiltration membranes one of our most versatile products. Alfa Laval offers a comprehensive range of UF membranes with different characteristics and properties.

Bring cost efficiency to your UF membrane process

- Cost-effective operation due to low energy consumption

- Efficient – no need to replace/dispose of the cartridges or consumables used in traditional dead-end filtration

- Excellent chemical and thermal stability with service life up to several years

- Low start-up costs compared with other solutions

- Flexible – available in different combinations of length, diameter and spacer size

Alfa Laval offers different ultrafiltration membrane types

The ultrafiltration membranes range from 1,000-100,000 molecular weight cut off (MWCO), and the applied pressure is relatively low. Salts, sugars, organic acids and smaller peptides pass through the pores while proteins, fats and polysaccharides are retained.

With our ultrafiltration spiral membranes you can fractionate a feed stream into two distinct streams, with each stream containing dissolved components with different molecular weights.

UF-pHt™ series

UF-pHt™ membranes tolerate high temperatures and pH values. The membranes are made of polysulphone or polyethersulphone on polypropylene support material. MWCO values range between 2,000 and 100,000 Dalton. Most of the spiral membranes are USDA approved and Halal certified.

UF-PP series

The UF-PP membranes are made of fluoro polymer, polysulphone, regenerated cellulose acetate or composite fluoro polymer on polypropylene support material. MWCO values range from 1,000 to 100,000 MWCO. One type is Halal certified.

UF-PET series

The UF-PET spiral membranes are based on polyester support material. The polymeric membrane is made of polysulphone, polyethersulphone or regenerated cellulose acetate with up to 100,000 MWCO values. Certain types are USDA approved and we can offer products with Halal certificates upon request.

Dairy series

Alfa Laval has two series of spiral membranes tailor-made for dairy applications: Dairy UF-PET and the Dairy UF-pHt™.

The dairy UF-PET spiral membranes, which are manufactured with polyester support material, are available with MWCO values between 5,000 and 10,000 Dalton.

The dairy UF-pHt™ spiral membranes, which are cast on polypropylene backing paper, are available with MWCO values between 5,000 and 20,000 Dalton.

Both types are USDA approved and we can offer products with Halal certificates upon request.

Our ultrafiltration membrane materials are compliant with all major regulations

Our spiral wound membrane materials are compliant with all major regulations

All membrane materials used for both flat sheet and spiral wound membrane configurations meet EU Regulation (EC) 1935/2004, EU Regulation 10/2011, EU Regulation (EC) 2023/2006 and FDA regulations (CFR) Title 21, and are suitable for use in food and pharmaceutical processing applications. Compliance also extends to the related equipment and fittings, including items such as plate-and-frame units, element housings and pumps, supporting safe and efficient spiral membrane filtration in a wide range of industries.

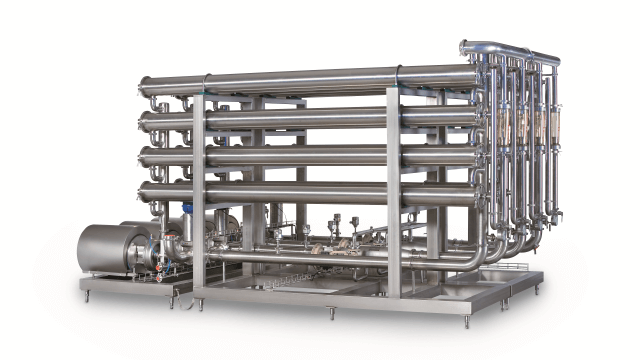

How it works

The basic technology behind membrane filtration involves using a semi-permeable membrane to separate a liquid into two distinct streams.

Pumping this liquid across the surface of the membrane creates a positive trans-membrane pressure that allows any components smaller than the porosity of the membrane to pass through, forming the permeate.

Any components larger than the pore size simply cannot pass through, and remain behind in what is called the retentate. The surface of the spiral wound membrane is kept free of blockages by the force of the liquid flow moving parallel to the membrane surface.

Construction of the ultrafiltration spiral membrane

Efficient spiral membrane filtration

A spiral membrane comprises of several membrane 'envelopes' with two membrane sheets separated by a permeate spacer mesh, each glued to a central permeate collection tube.

Between each pair of envelopes there is a spacer which creates the feed channel, allowing the feed to flow across the length of the spiral wound membrane, whilst the permeate passing through the membrane into the membrane envelope flows in a spiral pattern to the permeate collection tube.

Red = Feed/retentate.

Green = Permeate.

The flow pattern in a UF spiral membrane where red represents the feed/retentate and yellow the permeate.