Module M37

The Alfa Laval module M37 is specially designed for ultrafiltration (UF) and microfiltration (MF) of high viscosity products (50-250 cP) and fermentation broths. The module is particularly suited for use in industries such as biotech and pharma, food and beverages as well as pulp and paper

Improved products and processes

Ultrafiltration (UF) is unique in that it allows liquids to be separated, concentrated and purified, all at the same time. Water and low molecular-weight substances pass through the membrane whilst high molecular-weight substances are rejected.

The composite structure of our microfiltration (MF) and ultrafiltration (UF) membranes, consisting of a support layer for mechanical strength and a thinner selective layer for the separation, combines the best of two worlds: High mechanical strength and a high capacity/flux.

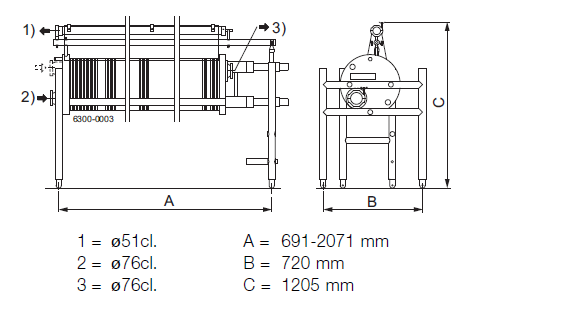

Plate-and-frame module, M37

The Alfa Laval plate-and-frame M37 module is our high-concentration module for liquids of extremely high viscosity. Many products are non-Newtonian so tend to thin as flow velocity is increased. This effect is fully utilized in the extraordinary design of the thin-channel system of the module M37, making the modules usable for products untreatable by most other UF systems.

The high-concentration Alfa Laval module M37 is developed to meet the future demands for optimized flow dynamics, low energy consumption and low-pressure operation. It is available with membrane area sizes up to 27 m² and it can operate at temperatures up to 80°C, pressures up to 15 bar and pH between 1 and 14. It can be equipped with the entire range of flat sheet ultrafiltration and microfiltration membranes available from Alfa Laval.

Alfa Laval PilotUnit Combi-50 UF/MF

The Alfa Laval PilotUnit Combi-50 UF/MF is a handy and versatile pilot-scale membrane system comprising an Alfa Laval plate-and-frame module of the type M37 or M38. It is a complete system with necessary pump, valves, tank etc. which needs only power supply, compressed air, water and feed product to operate.

The Alfa Laval PilotUnit Combi-50 UF/MF is a handy and versatile pilot-scale membrane system comprising an Alfa Laval plate-and-frame module of the type M37 or M38. It is a complete system with necessary pump, valves, tank etc. which needs only power supply, compressed air, water and feed product to operate.

Benefits

- processing of substances of extremely high viscosities

- processing of highly concentrated products

- low energy consumption

- standard modules with membrane areas up to 27 m²

- operation at low pressure

- rugged yet flexible stainless steel and polymer construction

- open channel design for handling of wide range of viscosities

- easy membrane failure detection and exchange on site

- accurate production up-scaling by increasing size or number of modules

- sanitary design with all materials in compliance with FDA and EEC regulations

How it works

The plate-and-frame module from Alfa Laval is designed with open channels across the membrane surface. The feed stream/retentate flows through these.

The membrane itself is supported by hollow plates with numerous slots that allow the permeate to collect and be removed from the module via the permeate collecting tubes.

Plate-and-frame modules use the membrane itself, aided by lock rings or strips, to seal off the feed/retentate from mixing into the permeate channels. This also prevents any leaks from the plate stack itself.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.