H Series

Our H Series dairy separators is specifically engineered for milk skimming. These separators include industry-leading innovations to help dairies of all sizes achieve premium milk quality at low operational costs. This includes Alfa Laval’s unique Hermetic Design, which ensures smooth product acceleration for improved skimming efficiency and unmatched process flexibility.

Superior skimming efficiency to preserve milk quality

- Alfa Laval’s unique bottom-fed Hermetic Design provides superior skimming efficiency and maintains premium product quality

- The bottom-fed design reduces shear forces for gentle product treatment that preserves the size of the fat globules

- Hermetic seals on inlet and outlet prevent oxidation and reduce the foaming of the milk

- Easy adaptation to process conditions provides increased production flexibility and efficient CIP

- Energy savings of up to 60% thanks to the Hermetic Design

A wide range of hot milk separators

The Alfa Laval H Series has been specially developed for milk skimming. With a wide range of models, there is an H Series separator that is suitable for any dairy. They are also the market’s only separators with Alfa Laval’s bottom-fed Hermetic Design, ensuring far greater energy efficiency compared to traditional centrifuges. This is due to a combination of gentle product treatment and the use of efficient built-in pumps instead of paring discs. The result is more sustainable separation that simultaneously reduces your carbon footprint and your OPEX. Built with high-grade, corrosion-resistant stainless steel, our H Series separators are also proven to meet the highest hygienic standards with low total cost of ownership over a prolonged equipment lifecycle.

Features that make the difference

What sets Alfa Laval separators apart is what’s on the inside: a broad scope of unique and patented technologies that, taken together, help dairy customers achieve improved product quality along with superior hygienic confidence. They also make it possible to drastically decrease both water and energy consumption, reducing both operational costs and environmental footprint.

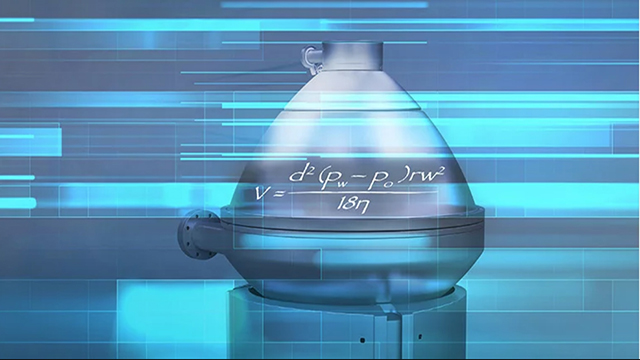

Hermetic Design™

Gentle acceleration, powerful efficiency

A unique air-tight bowl that enables improved product quality and drastically reduces power consumption.

eDrive™

Mechanical simplicity for higher efficiency and lower costs

A direct-drive system with fewer rotating parts that minimizes both maintenance and energy costs.

UniDisc™

New levels of capacity and hygiene

A radical new disc design that decreases cleaning needs while increasing flow rate by up to 20%.

eMotion™

Double the output per kWh

An innovation to minimize friction, which cuts the separator´s energy consumption and CO2 footprint by up to 70%.

Bactofuge®

Outstanding solids capacity

Continuous solid discharge ensures an intact and highly concentrated stream for onward processing or as a valuable by-product. This makes it possible to increase separation capacity.

The Separator Innovator

Alfa Laval invented the first disc stack separator over a century ago. Since then, we have led the way by constantly improving and reinventing centrifuge technology. Making it safer, more efficient, and more sustainable. Visit our Separator Innovator knowledge base and discover how we continue to revolutionize separation processes across industries.