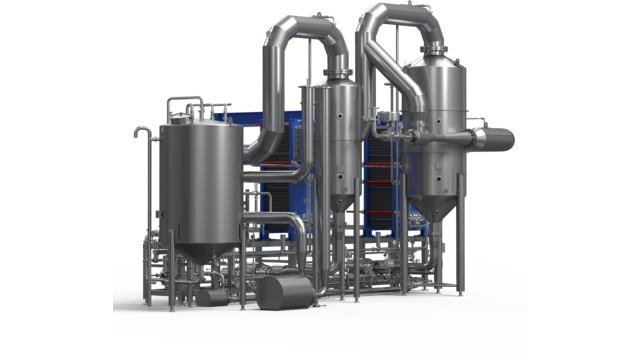

AlfaVap system

Alfa Laval AlfaVap evaporation systems are found in plants all around the world, handling a large variety of products. Thanks to the AlfaVap units´ compactness and exceptional thermal efficiency, the complete installation is very energy efficient and easy to install in small spaces. We offer complete evaporation systems optimized for your specific circumstances.

More compact, faster start-ups, higher thermal efficiency, and better product quality than shell-and-tube evaporators

- Versatile, economical evaporator for concentration of a various products across a broad range of industries

- Improved product quality due to fast start-up and shut-down times, high heat transfer efficiency, and short residence time – perfect for heat-sensitiv

- High energy efficiency due to lower steam use with multiple effects and thermal and/or mechanical vapour recompression units

- More uptime, less maintenance with minimal fouling due to self-cleaning effect created high turbulence and high shear rate

- Compact, space-saving footprint that is 50-70% shorter in height than shell-and-tube evaporators, reducing installation and service time and costs

Maximize uptime with the Alfa Laval AlfaVap rising film plate evaporator. This cost-effective climbing film evaporator concentrates process liquids that contain dissolved solids, easily handling higher media concentrations and viscosities than tubular evaporators.

Install AlfaVap rising film evaporator as a complete evaporation effect or a cost-efficient booster unit to increase existing evaporator capacity using the existing structures and controls. Its low height makes it easy to install on a single floor with a few or no pumps. This cuts installation costs.

Typical applications of a rising film evaporator include sugar refinery, sweetener, animal and plant-based protein, bioethanol and caustic evaporation duties.

Reduce your engineering requirements with Alfa Laval expertise, global process application development and support, and a complete range of evaporator solutions for a wide selection of applications and capacities. Our complete system designs include vessels, pumps, piping, ducts, instruments, and engineering.

The AlfaVap fit into our existing tuna fishmeal plant and concentrates stick water from 12% up to 40%. A conventional falling film evaporator would have required a whole new building.– Mr. Cobas, Managing Director, Conresa, Spain

Compared with shell-and-tube heat exchangers, the AlfaVap evaporators are more efficient. Evaporation occurs using less steam for economic reasons. We’ve cut our energy costs by 10%, while the company’s effective output has gone up.– Peter Simpson, Technical Manager, Chelsea Sugar Company Ltd., New Zealand

High energy efficiency

The high thermal efficiency of the plate evaporators makes it possible to use heat from different sources, such as mechanical and thermal recompression, as well as waste vapours from, for example, dryers.

The most effective way to reduce steam consumption in evaporation systems is to increase the number of effects. Each effect saves steam and cuts energy cost. Thanks to the compact design, an Alfa laval system can contain more effects in a given space than any traditional falling film system.

The small size also means existing falling film systems can be retrofitted with an extra Alfa Laval effect, resulting in up to 33% lower steam consumption.

Easy maintenance and more uptime

The highly turbulent flow in the AlfaVap plate evaporator makes it less susceptible to fouling. The special corrugated patterns ensure a high degree of turbulence over the whole plate. This turbulence not only reduces fouling but also makes chemical cleaning very effective. The result is a system with significantly less fouling, lower maintenance costs and more uptime.

All surfaces are easily accessible for maintenance and can be cleaned on site within the physical footprint of the unit.

Flexible capacity

The plate construction of AlfaVap makes it easy to adjust capacity to meet changing needs, simply by adding or removing plates, while retaining the existing frame.

High product quality

The low temperature combined with short residence time in the plate evaporator (due to a low hold-up volume) secures a high quality end product with minimum discoloration. The low hold-up volume also ensures fast, smooth start-ups with easy control.

Ideal solution for high viscosity fluids

AlfaVap plate evaporators maintain a high thermal efficiency, even when dealing with viscous liquids. An AlfaVap evaporation system can easily handle fluids well beyond 300 cP. For higher viscosities we recommend Alfa Laval AlfaFlash systems.

Benefits

- Energy efficient

- Compact installation

- Short residence time

- Easy and fast cleaning

- Flexible capacity

How it works

Evaporation is used for concentration of a liquid product.

Alfa Laval’s AlfaVap evaporation systems are based on a plate-and-frame design tailored for evaporators. The AlfaVap rising film evaporators use the cassette concept with the evaporator plates welded in pairs.

Steam is applied as a source of heat in the welded channels of the AlfaVap evaporator while the product passes through gasketed channels. As boiling occurs inside the AlfaVap, the mixture of vapour and liquid rises to the top of the evaporator. In the cyclone separator vessel the vapour and liquid phases are separated.

Vacuum is applied in the AlfaVap system to decrease the boiling point of water. This means that the boiling occurs at a lower temperature than 100 °C. For some applications the boiling point is as low as 40-50°C.

The vacuum in the evaporation system is created by a vacuum pump and by condensing the vapours from the last effect of the AlfaVap system in a condenser tailored for vacuum condensation. The most effective way to lower steam consumption in evaporation systems is to increase the number of effects. Each effect saves steam and cuts energy cost. For optimum steam economy, the system usually consists of multiple effects as well as some type of vapour re-use, like TVR (Thermo Vapour Recompressor) or MVR (Mechanical Vapour Recompressor).

A complete AlfaVap system includes the plate evaporators, preheaters, cyclone separator vessels, TVR or MVR, pumps, instruments, valves, ducting and piping and a local PLC with control panel.

Main building blocks of an AlfaVap evaporation system