2023-03-13 Product news

Discover Alfa Laval innovation for safe and efficient solid-liquid separation at Austmine2023

Austmine 2023 will focus on transforming our future, with technology innovation in separation playing a key role in enabling circularity, profitability and safety in mining & mineral processing.

Event details (this event has concluded)

When: 9 - 11 May 2023

Where: Adelaide Convention Centre

Global demand for mining products continues to grow due to population growth, urbanisation and the energy transition. By dewatering waste streams with Alfa Laval separation technology, mine sites can recover and re-use up to 80% of process water while improving safety and environmental impact by moving away from the traditional practice of storing the slurries in tailings dams.

Alfa Laval solid bowl centrifuges offer the highest large capacity in the market, specifically engineered with a robust design and full wear protection for high reliability.

With 95+ years' direct market presence, the company ensures equipment uptime & performance with local service centres and field service engineers servicing even the most remote mining sites.

How separation technology transforms operating economics, safety and sustainability

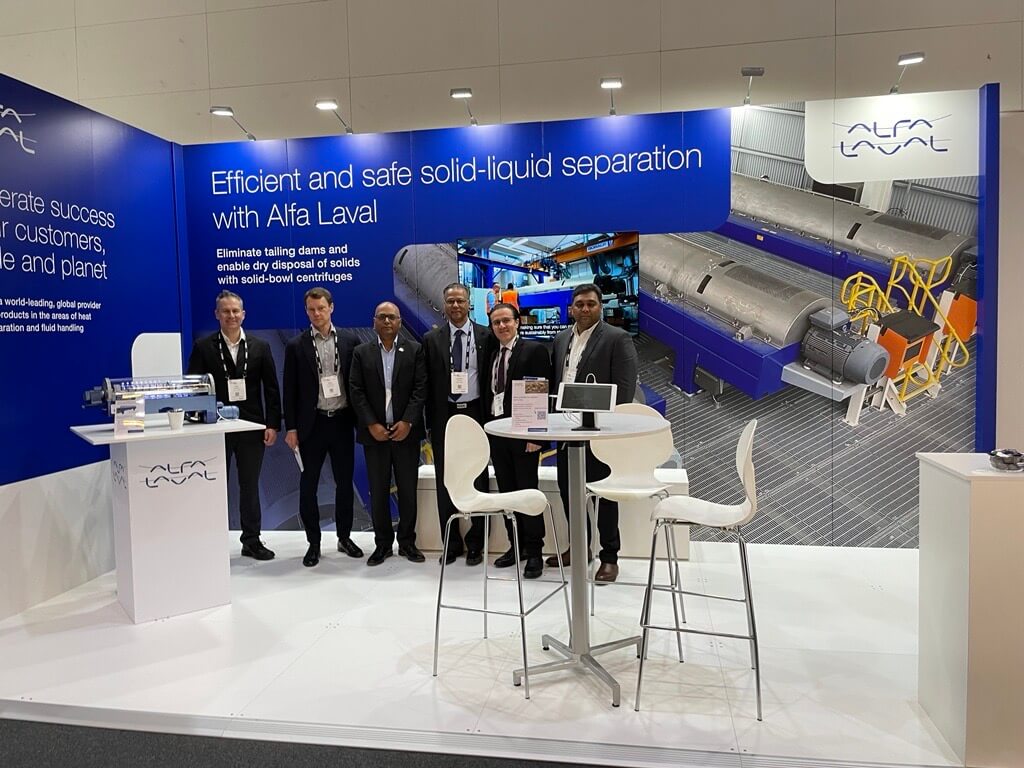

Visit the Alfa Laval stand (#513) to learn more about Alfa Laval technologies for tailings dewatering and other heavy-duty solid-liquid separation applications including exploration drilling.

Our senior mining and business managers look forward to meeting you for a confidential discussion about your process optimisation strategy and dewatering requirements.

As Spotlight Sponsor, Alfa Laval is proud to present as part of the Collaboration Laboratories.

Visit Austmine website for more event information

Mining and minerals

Optimise key processes in mining & mineral processing to boost production together with operational safety and sustainability.

Meet the expert

Topic: Alfa Laval Solid Bowl Centrifuge Technology for Mining Industry

Presenter: Harvey Foroush

Overview

- Reduce the mine footprint and environmental impact by eliminating tailings dams and moving towards dry stacking

- Lower the rehabilitation costs at the end of mine life

- Increase profitability by recovering fine & ultra-fine particles of product from waste stream

- Recover water and reuse it in the plant instead of wasting the water in a tailings pond

About the presenter

Based in Brisbane, Harvey helps mining companies across Australia optimise processes, improve the bottom line and reach sustainability targets.

As a Technical Manager in Alfa Laval Australia's Energy division, he has been focusing on solid bowl centrifuge installations for tailings dewatering and dry tailings disposal across mines in Queensland and New South Wales.

Harvey is an Engineers Australia member and graduated in Mechanical Engineering from Azad University, Iran.

Join the live presentation in Co-Lab Tech Talk 'The Waterless Mine'

10 May 2023, 2 - 3:30pm

P3 Product details

Alfa Laval P3 solid bowl centrifuges are specifically designed for heavy-duty mining and minerals dewatering applications and can process 50-60 dry tonnes per hour.

Tailings dewatering

The robust design and large capacity of Alfa Laval solid bowl centrifuges have proven the perfect solution for safe and secure dewatering of mining tailings.