Slurry treatment in tunnel boring

Alfa Laval has a range of centrifuge decanters for cost-effective control of large volumes of solids in tunnel boring applications (TBM). Efficient separation in a continuous process increases the dry solids content, while saving costs of water recovery. The high capacity per footprint and low operating costs help to increase job-side productivity and your ability to compete at the top of your business.

Compact, robust equipment for continuous operation and high separation efficiency

- High degree of erosion protection and capacity contribute to short payback time

- Flexibility to handle a variety of solid-liquid separation duties

- Fully enclosed system improves working environment

- Automated conveying speed gives optimal solids dryness

- Improved sustainability benefits – solids can be directly landfilled so less transport required

Innovative technology for civil drilling

Alfa Laval decanter centrifuges are a key component in the efficient treatment of slurries in tunnel drilling. The technology efficiently removes most of the fine particles that traditional slurry treatment equipment cannot.

The centrifuge can be adjusted to suit specific requirements. For example, you can vary the bowl speed to ensure the exact G-force required for the most efficient separation. The conveying speed and the pond depth can also be adjusted for the desired balance between liquid clarity and solids dryness.

Specially designed and built for tunneling environments, the Alfa Laval decanter centrifuges cope with abrasive and coarse particles and can handle large volumes of feed solids and various flow rates.

The decanter centrifuges are available with a range of modules ideally suited for every kind of solids separation in slurries. They range from fully automated operation to simple “hands-on” capabilities. Whichever you choose, you can look forward to effective solutions to your slurry dewatering and separation needs.

Civil wastewater management

The world's increasing population and the increased level of urbanization creates major transportation issues, which are often solved with transportation tunnels for subways and metros in the larger cities. Construction drilling helps create pipelines and tunnels of many different sizes, using the Alfa Laval product CDNX for solids control and waste water management.

The importance of cleaning waste water at your construction site

The construction and engineering industries play a crucial role in the continued social and economic development of our world. Any serious project (whether public or private) is now subject to requirements to minimize impacts on people and the environment. A contractor’s environmental impact assessments (EIA) and environmental management plans (EMP) set the minimum levels for efficient use of resources, the protection of biodiversity, climate change and, not least the risk of accidents and the protection of our health in general.

An important part of a construction project’s EIA is water management, especially in civil engineering. Water plays a key role whether it is used in excavation and foundations, to cool machines, keep pressure, move solids (for example tunnel boring machines, drilling rigs and cutting machines) or as a means of cleaning. Rainwater and effluent seepage also need to be managed. Companies that can optimize consumption and ensure water meets the national and local regulations regarding cleanliness will always be at an advantage.

Alfa Laval’s range of centrifuge decanters are built to meet the high environmental demands for solid-liquid separation in tunnelling construction and similar applications. The proven separation technology removes the finest particles (unlike sedimentation tanks) making it easier to meet requirements for water disposal or re-use, such as suspended solids, acidity (pH), and biological and chemical oxygen demand. Low operating costs and high separation capacity help contractors to compete effectively and to meet these evermore-stringent environmental demands.

How a decanter works

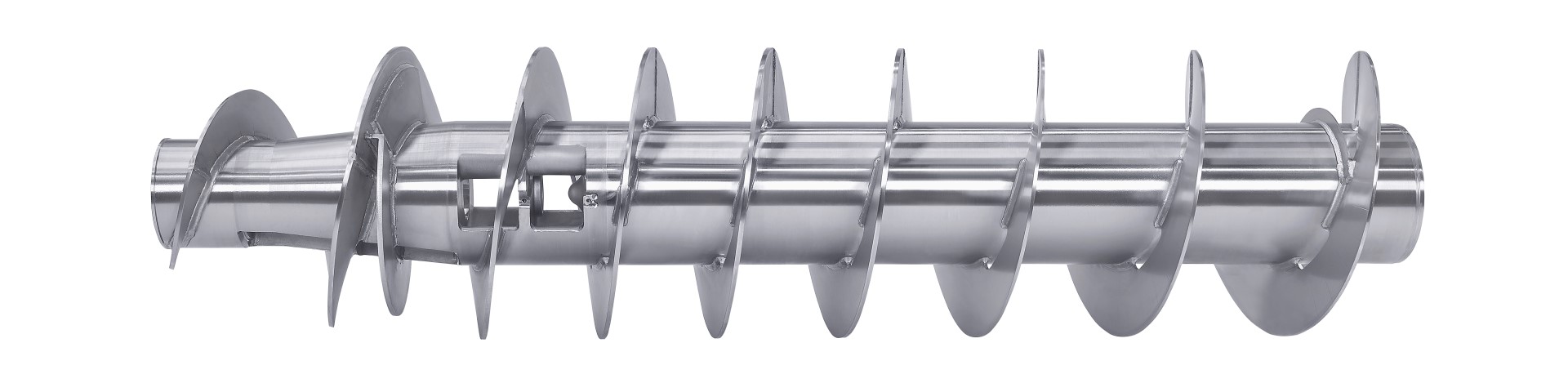

The rotating assembly is supported on a compact welded box beam frame with main bearings at both ends. The in-line main motor is flange- or foot mounted onto the unit with adjustable brackets for belt tension adjustment. The bowl is driven at the conical end by an electric motor with a V-belt transmission. The bowl, conveyor, casing, inlet tube, outlets and other parts in contact with the process media are made of AISI 316 or duplex stainless steel with tungsten carbide inserts in the areas most susceptible to wear.

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet rotor. Centrifugal forces cause sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl.

The design enables the decanter to scroll out high loads of solids without blockages caused by high levels of dryness. Only the very driest fraction of the sludge cake leaves the bowl through the solids discharge openings into the casing.

Separation takes place along the total length of the cylindrical part of the bowl, and the clarified liquid leaves the bowl by flowing over adjustable plate dams into the casing. The decanter centrifuge can be adjusted to suit specific requirements by varying the bowl speed, the conveying speed, the pond depth and the feed rate.

Get a quick quote!

Get more details on a construction drilling decanter for waste water and slurry treatment by generating a quote instantly. Click on the link or use the QR-code to get to the quotation template.

*You will be redirected to another platform.

Let’s work together to reduce your disposal costs

If you are looking for ways to reduce the cost of slurry treatment and disposal in your tunnel drilling, contact Alfa Laval today to learn more about our proven technology and cost efficient solutions.