How to protect your cooling tower system from fouling, calcium deposits and corrosion with a plate heat exchanger interchanger

Fouling, calcium carbonate deposits and possible damages from chloride attack are well-known problems connected to open cooling towers.

DATE 2023-11-28Open cooling towers are one of the most widely used utility equipment in everyday heating, cooling, aircon / air conditioning and ventilation (HVAC) applications as well as industrial and manufacturing plants.

Cooling towers are a popular choice as they offer one of the best inventions for heat rejection of cooling water, work efficiently and with low capital investment, and harness evaporative cooling where 60-80 per cent of the heat transfer is by evaporation and the rest by sensible heat.

A key component in this system is the cooling tower interchanger. This application provides protection from the harmful effects of open cooling towers on downstream equipment. The interchanger also helps to save water and water treatment costs. The payback period is normally less than two years.

Contact your local expert

Suria Moodley

HVAC Industry Manager, Alfa Laval Australia

Building on her engineering background, Suria helps HVAC, data centre and light industry companies optimise their system design, performance and efficiency. She focuses on heat exchanger technology, design and innovation within Alfa Laval Australia, where she also held technical roles working with the food and pharmaceutical industry before.

In addition to her current role as heat exchanger specialist, Suria also works with partners and distributors that represent Alfa Laval heat exchanger products in the Australian market.

She is a member of AIRAH and a proud supporter of Women in AIRAH.

Understanding the root cause of cooling tower fouling

One of the main components of cooling towers is the packing which is made of lightweight plastic material. The packing or fill provides a heat transfer surface for evaporation without restricting the airflow.

A narrow channel spacing is more efficient with more heat transfer area per meter cube, however also more prone to fouling from airborne particles.

The choice between a narrow and wider channel spacing is a balance between efficiency and risk of blockage usually one would see airborne debris or biological growth on the packing.

Calcium carbonate or scale are less of a problem as the surface temperatures are the lowest in the loop and calcium carbonate remains dissolved at cold temperatures.

Challenges that come with open cooling towers

The operation of open cooling is simple and straightforward. In this cooling tower diagram, we can see the water is sprayed over the tower packing and the air is drawn up by the fan and discharged from the top in this process water is cooled with evaporation and returned to the plant.

However, there are many inherent problems that cause major challenges with downstream equipment:

Open cooling towers are excellent air fresheners as whatever is in the air ends up in the water and hence in the downstream plant equipment causing fouling secondly and more importantly the tower acts as a mineral deposit box. When the water evaporates, it leaves behind unwanted minerals including salts, calcium carbonate and chloride ions.

Evaporated water must be replaced by makeup water, and this brings even more unwanted minerals to the recirculating water. Flushing is needed to remove the minerals from the system but it is usually not done regularly due to high water costs.

Lastly, costly chemicals are added to reduce the harmful effects of these accumulated minerals by the water treatment companies that monitor PH balance and conductivity.

Accumulation of minerals including Calcium Bicarbonate (CaCO3) and Chloride (CI)

Calcium carbonate behaves opposite to household sugar. In other words, it precipitates out of solution and solidifies when in contact with hot surfaces, just like your kettle at home.

As a rule of thumb, the hotter the surface, the more the deposit and in the context of the cooling tower, this is mostly affecting the water-cooled condenser tubes.

Let’s look into this unwanted mineral calcium carbonate:

If the cooling loop water contains 100 milligrams per litre of calcium carbonate at the start, this concentration is equal to 100 ppm. When half the water in the cooling loop evaporates and is replenished the concentration increases to 150 ppm and this can double or triple over time. Without flushing, it can reach unacceptable levels and start causing serious problems.

Similar accumulation happens with chloride ions - they reach excessive levels and cause corrosion to downstream cooling equipment.

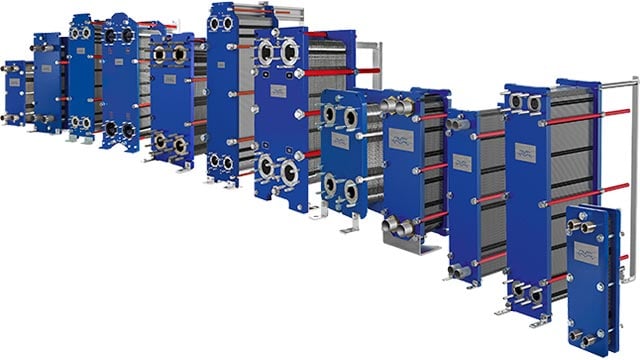

Gasketed plate heat exchanger as interchanger in a cooling tower system

An Alfa Laval gasketed plate heat exchanger (e.g. Alfa Laval Industrial Line) located close to the cooling tower will protect the plant from the harmful effects of fouling and accumulated minerals. A plate heat exchanger can be implemented both for existing cooling towers and for new cooling tower purchases.

Two of the main benefits of using an interchanger:

- Downstream plant equipment savings with better heat transfer efficiency to reduce maintenance costs and reduce replacement or repair costs

- Recirculating water due to a smaller cooling water loop. This means savings from less chemicals and reduced water consumption, especially when flushing. There are also savings from lower pumping costs by avoiding calcium carbonate build-up in the pipes.

Importance of certified heat exchanger performance

Some words of caution: Please make sure to specify AHRI performance certification when you’re purchasing the gasketed plate heat exchanger. A selection with tolerances can be made by manufacturers in this application.

A selection tolerance of half a degree Celsius would result in halving the size of the heat exchanger. However, the performance will be unacceptably higher due to the cooling water temperature to the plant. With tens and thousands of open cooling towers installed on some sites, there is a huge opportunity for savings by installing an interchanger.

Remember that gasketed plate heat exchangers can be retrofitted in existing cooling tower systems.