Lube oil processing

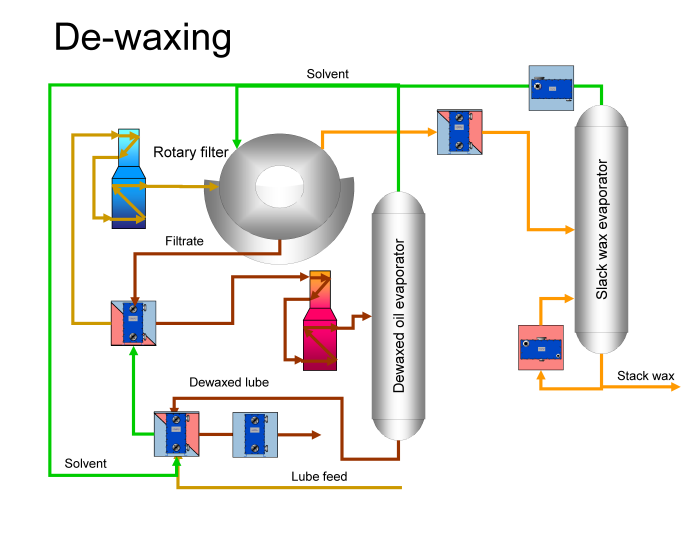

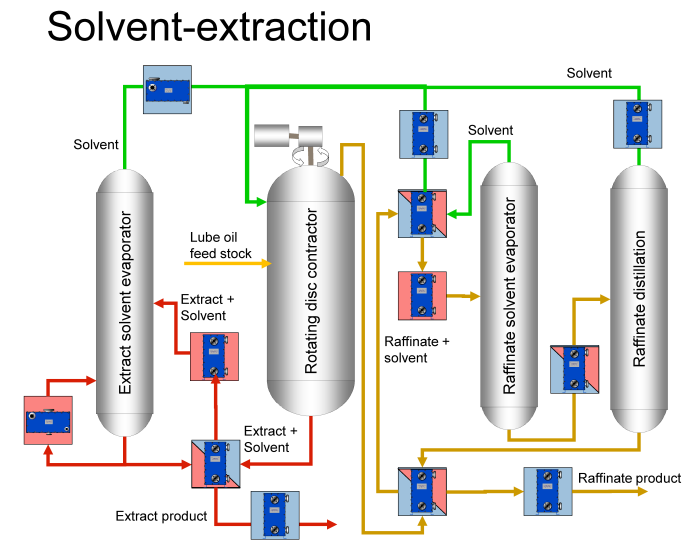

Removing the aromatic content and wax before the lube base stock is ready for blending involves critical refinery processes. Heat exchangers installed in these processes must provide energy to distillation columns, condense vapours, cool products and recover energy. Compact Alfa Laval heat exchangers are excellent tools to maximize efficiency using minimal plot space.

Optimizing refinery lube oil processes

Making petroleum lubricating oils from crude oil calls for smart processes that save energy, reduce maintenance, increase production and cut investment costs. Alfa Laval has the expertise, technology and services to meet refinery needs.

Increasing energy efficiency in refinery lube oil processes

Whatever solvent is used to remove aromatic compounds and wax, several columns are needed to recover the solvent from extract, raffinate, wax and lube oil. To minimize the energy input to these evaporators and fractionating columns, it is necessary to recover as much energy as possible from the hot fractions and reuse it to heat the column feeds.

High-efficiency Alfa Laval heat exchangers maximize energy recovery using minimal plot space, thereby significantly reducing energy input to the process.

CAPEX savings

Traditional shell-and-tube heat exchangers can be expensive. This is because energy recovery for lube oil processes usually requires several large, bulky exchangers in series. Installation costs, including installation on construction, push costs even higher. High-efficiency Alfa Laval heat exchangers, on the other hand, help reduce investment and installation costs while delivering a maximum efficiency on minimal plot space.

Proven technology for refinery lube oil processes

Alfa Laval has more than 100 heat exchangers operating as interchangers, reboilers, condensers, heaters and coolers in lube oil plants around the world. Some lube oil plants have installed an Alfa Laval compact heat exchanger in every position that requires a heat exchanger.